Thermal Lamination

The Enprom Thermo Laminating machine has been specially designed for the flexible packaging market, enabling pouches to be finished in the highest quality.

Produce packaging for a range of markets including:

- Pet food

- Wipes and cosmetics

- Crisps and snacks

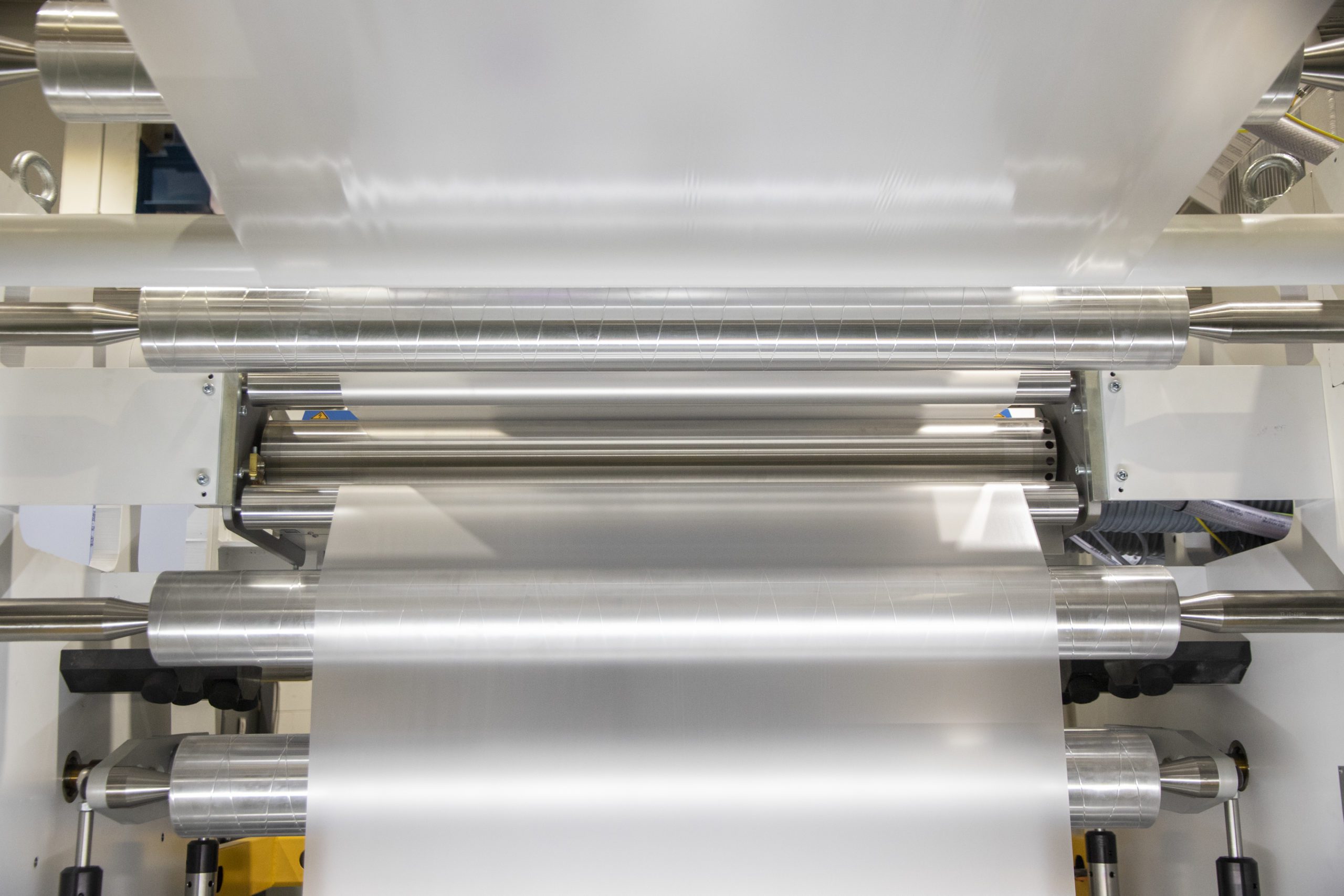

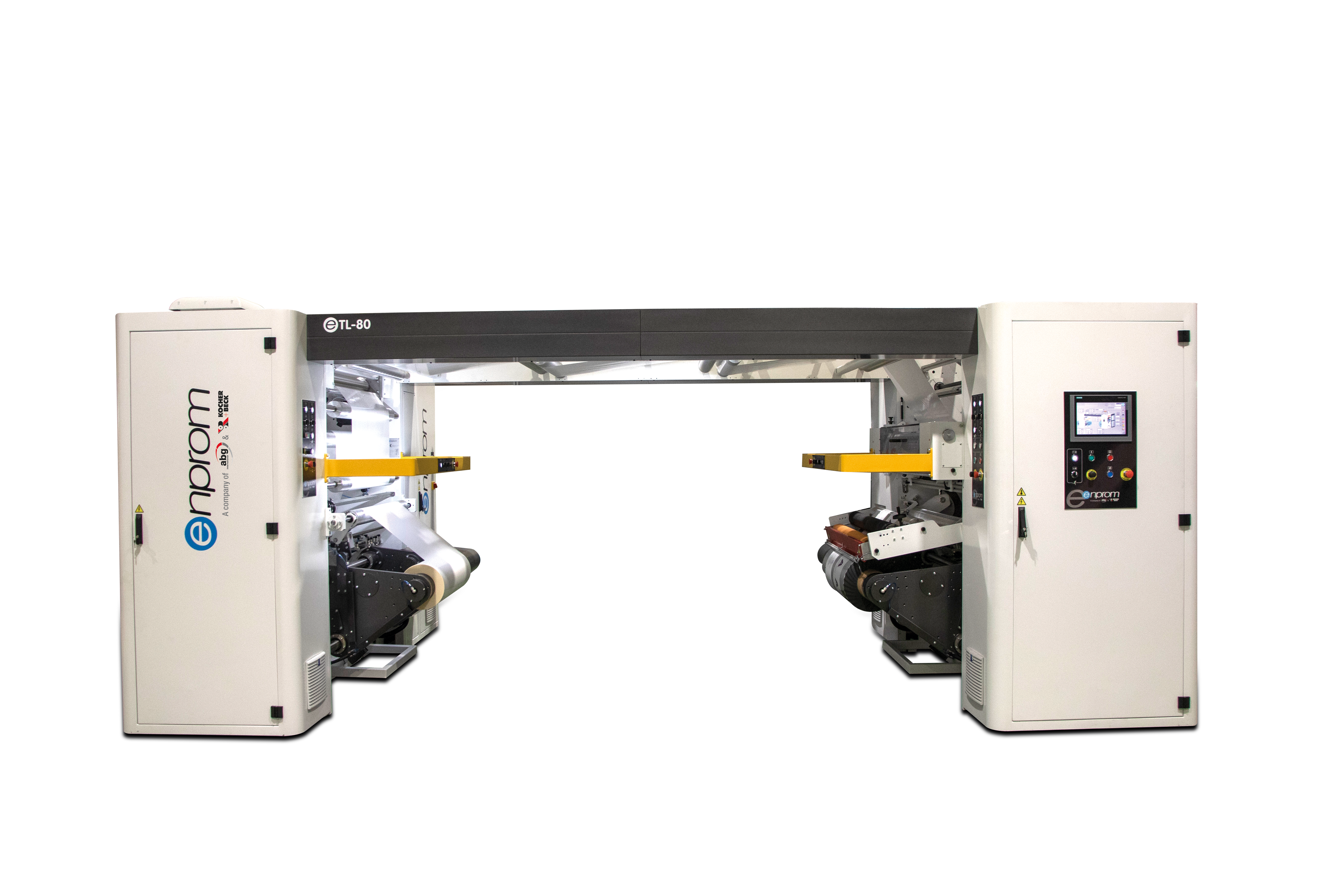

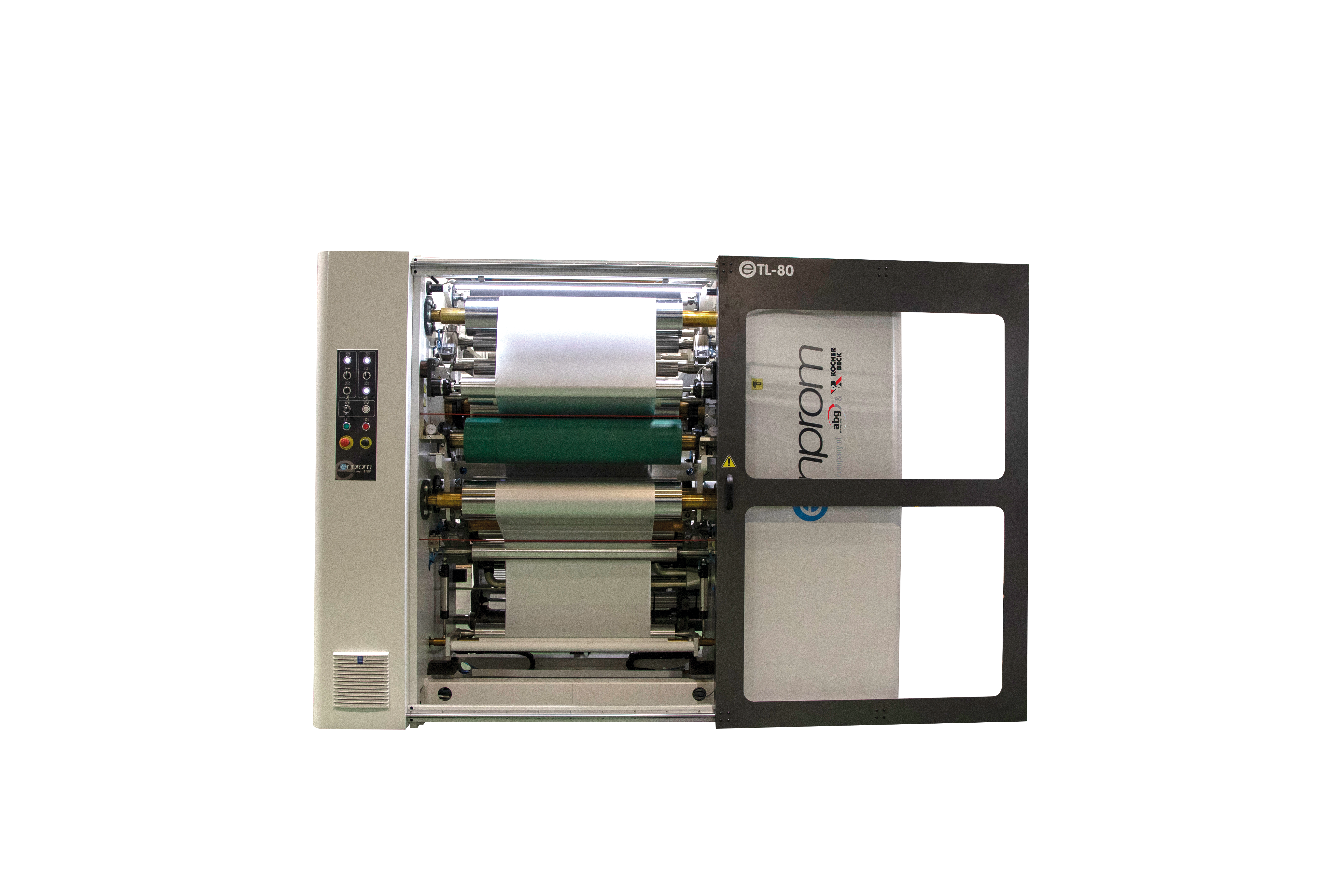

The eTL has two parts joined by the web path. The first unit supports two unwinders with its control tension units and corona treatment. The second unit contains the rewinder and laminator unit. This machine is designed to shorten the web and reduce waste, and is also capable of being used for short run flexible pack jobs for immediate time to market.

Able to laminate different flexible packaging production including pet food, wet wipes, crisps, snacks, cosmetics, coffee and tea the eTL has multi market applications.

- Higher Production speed

- Shorter web path allowing waste reduction

- Food safe, no chemical reaction, no chemical migration

- Unwinder and rewinder diameter detector to reduce the set up

- Pneumatic chucks in unwinder and rewinder units for easy and fast loading of rolls

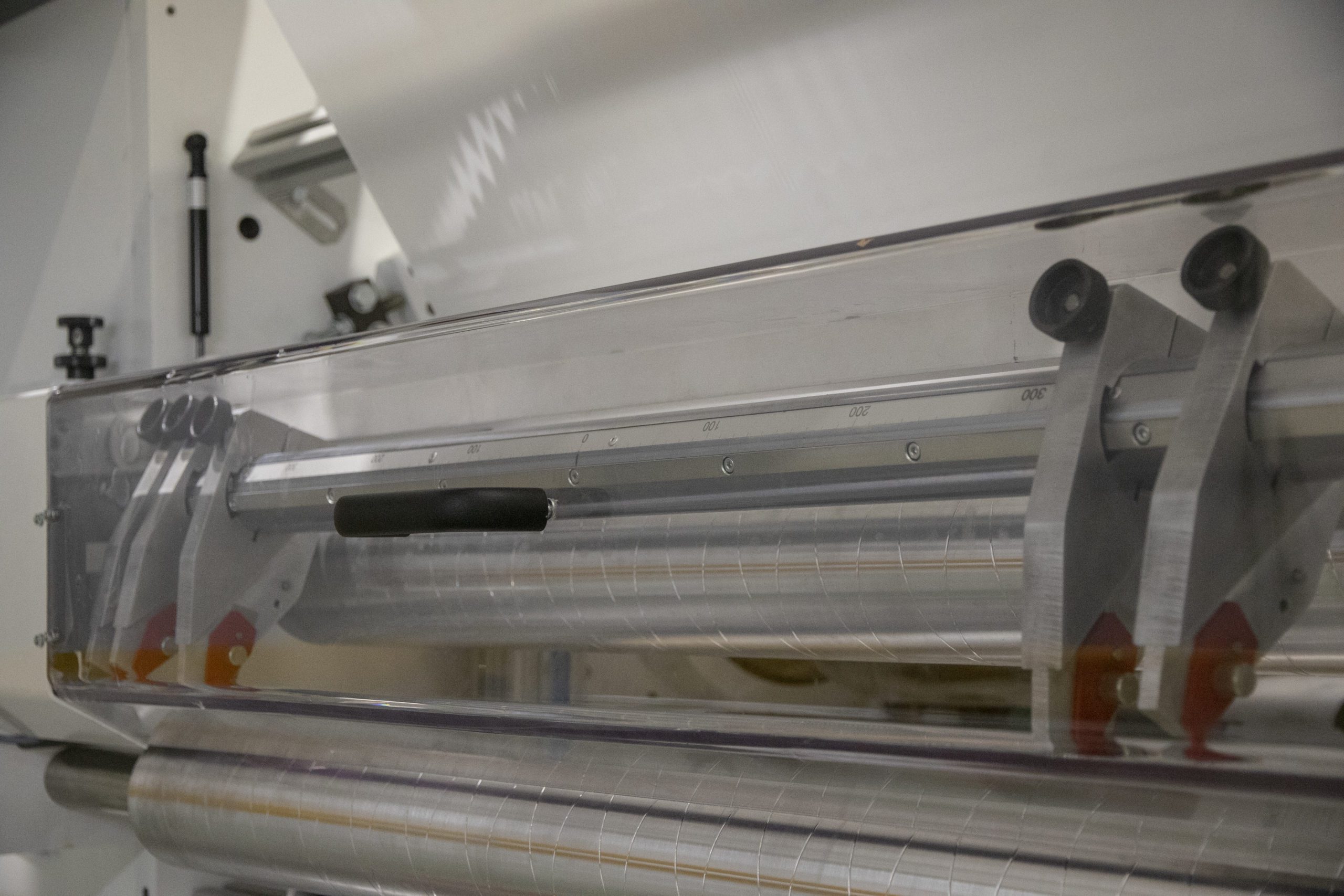

- Slitting unit for finish the roll with trim or different rolls

- Safety guard rewinder pressure roll, ensuring operator safety

- Electronic control pressure on the reel rewinder for better tension control and quality

- Integrated equipment: corona, chillers and heaters

- Regenerative high-performance control equipment

- Intuitive software that is easy to use and allows you to easily monitor productivity

View and download the eTL Thermal Laminating Machine Technical Specification by clicking here.