Non Stop

TECHNOLOGY

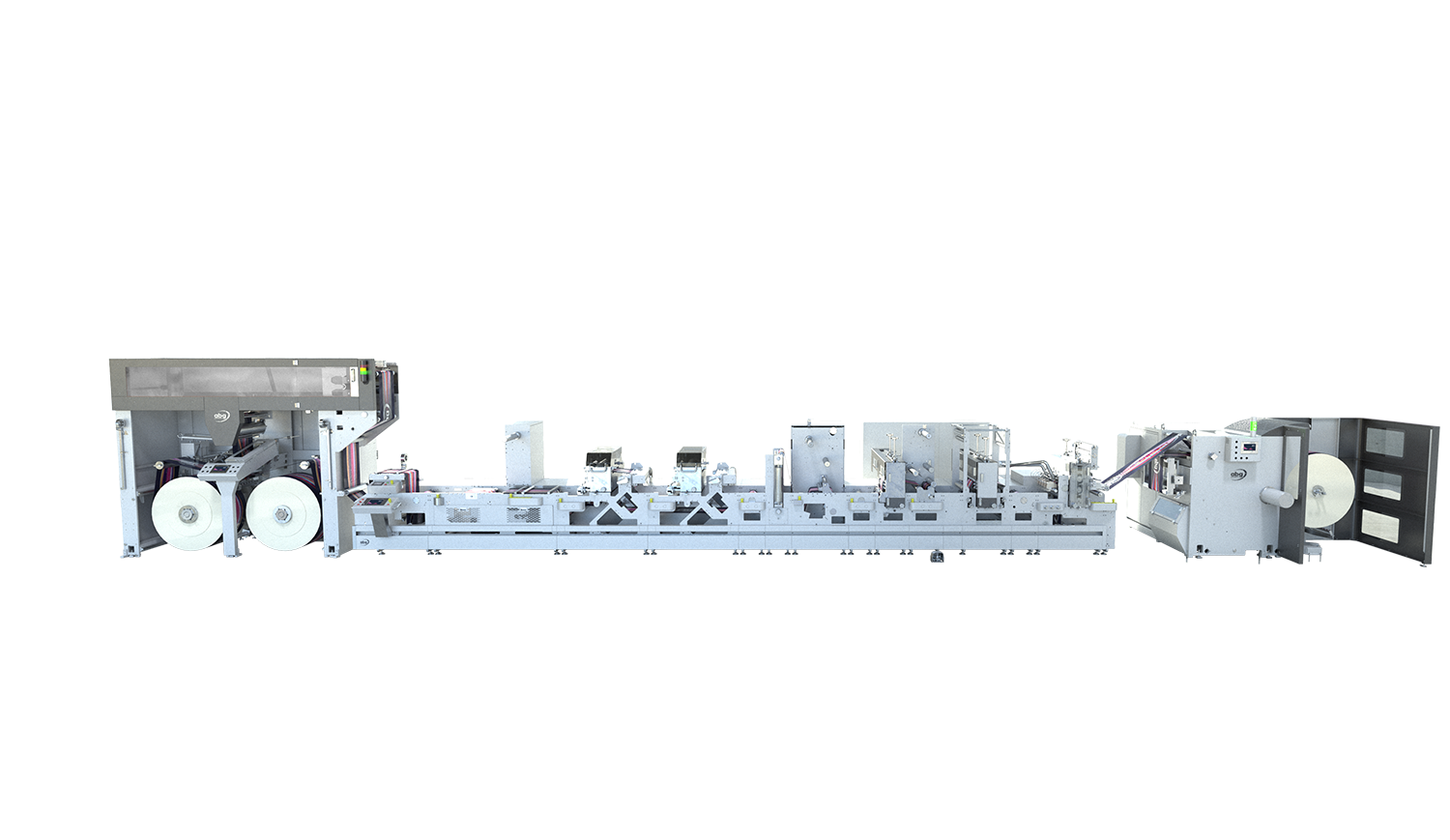

Our range of Non Stop Winders are industry leading. They utilise the latest servo technology, as opposed to traditional mechanical solutions – enhancing both product quality and line productivity whilst also reducing material waste.

The Non Stop Winding options are a must have for any printing press and perfectly compliment our Digicon Series 3 or Converter.

Delivering the best tension control

in the market

Our Non Stop range includes 5 machines with a range of cutting techniques to provide the best butt splice in the market. With a choice of unwinders and rewinders to best suit your production needs, all designed to:

- Reduces waste

- Enhances quality

- Increase capacity

About

Non Stop Technology

- Non Stop Range

- Non Stop Unwind (NSU)

- Automatic Servo Unwind (ASU)

- Automatic Servo Rewind (ASR)

- Automatic Servo Rewind Plus (ASR+)

- Dual Automatic Servo Rewind (ASR2)

For customers looking for ultimate efficiency and productivity we are the only provider that can offer one single point of sales and service.

- Increased capacity – up to 20% additional capacity created – reducing the number of presses needed.

- Increased product quality – increase product quality and consistency by running at a stable web tension.

- Environmentally efficient – reduced material waste on machine start up and roll changeover.

- Camera compatible – fleyeVision camera inspection technology is fully compatible with the non-stop range.

- Versatile – entry level and advanced versions available.

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

brochure by clicking here.

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

Spec Sheet by clicking here.

Our original Non Stop unwinding solution. With the capacity to hold two 1000mm rolls, our NSU is the first in optimised efficiency.

- Available in 580mm & 670mm web widths

- Can only be supplied alongside ABG converting equipment

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

brochure by clicking here.

The ASU offers a new-generation of Non Stop Unwind equipment utilising the latest in servo technology for unrivalled web tension control.

- Available in all web widths: 370, 450, 580, 670 & 850mm

- Full close-loop tension control

- Interfaced package to suit any ABG or third-party machinery

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

brochure by clicking here.

The ASR is our basic Non Stop rewind solution. It enhances the efficiency of your finishing solution by removing the need to stop for

a roll change.

- Bump and cut transfer

- Maximum 1000mm finished roll

- Maximum 500mm running finished roll

- Best suited for paper products

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

brochure by clicking here.

The ASR+ is ABG’s latest rewind solution, utilising our Vectra anvil and auto-cutting technology.

- Anvil and Auto Cutting module

- Maximum 1000mm finished roll

- Maximum 500mm running finished roll

- Core Diameters include 3”/6”

- Best suited for unsupported films and other product material

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

brochure by clicking here.

The ASR2 is a dual Non Stop Rewind solution with the capacity to hold two 1000mm rolls simultaneously.

- Cutting transfer unit between the 2 rewinds

- Increased roll change over period for operator

- Best suited for unsupported films and other product material

- Only Non Stop Rewinder available for the 850mm web width

![]() View and download the Non Stop Technology

View and download the Non Stop Technology

brochure by clicking here.

Related

Products

A fresh look at

digital finishing

Innovative digital

finishing machines

Easy to use, quick to set up, fast, automated, flexible

and reliable – just some of the reasons clients across the globe choose ABG machines.