FleyeVision

fleyeVision assures full quality throughout your entire label production. The system uses digital line cameras with resolutions of up to 8k to detect printing errors such as scratches, hickies and text irregularities as well as register shifts and colour deviations.

Did you know

fleyeVision can also be used to inspect reflex films and holograms.

FleyeVision offers barcode and OCR control and allows variable data matching, pdfComparision, gapControl, advance reporting and Zero Point to avoid errors and improve efficiencies.

fleyeVision with the zero point module is now fully compatible with ABG Connect, allowing for a fully automatic camera set up without camera intervention.

About

fleyeVision

- On a printing press

- On a converter/rewinder

- On a pharmaceutical control machine

- Available Options

- Zero Point

- Live front and back side inspection during printing

- Warning function via indicator light and alarm

- Waste reduction and time and money savings due to early stage error detection

- Logging of the entire production with advance reporting

- 100% inspection of all products

- Display of errors and automatic positioning on the splice table for operator actions

- 100% inspection of all products

- Machine stop and error positioning

- Error Handling

- Re – inspection with 2nd fleyeVision for 100% safety

- If necessary, stop at 3rd splice table for operator action. Acknowledgement by signature

- Special protocol and administration features in accordance wirh FDA 21CFR Part 11.

- 100% Inspection

- FleyeVision ocrControl

- FleyeVision barcode Control

- FleyeVision gapControl

- Delta E Control

Zero Point for ABG Connect –

- Full automatic camera set up of print phrase inspection without operator intervention. This should be linked to JDF/JMF

- Job data to be supplied from the customer system

- Unique to ABG

- Retrofittable as with all ABG modules

![]() View and download the fleyeVision

View and download the fleyeVision

brochure by clicking here.

Related

Products

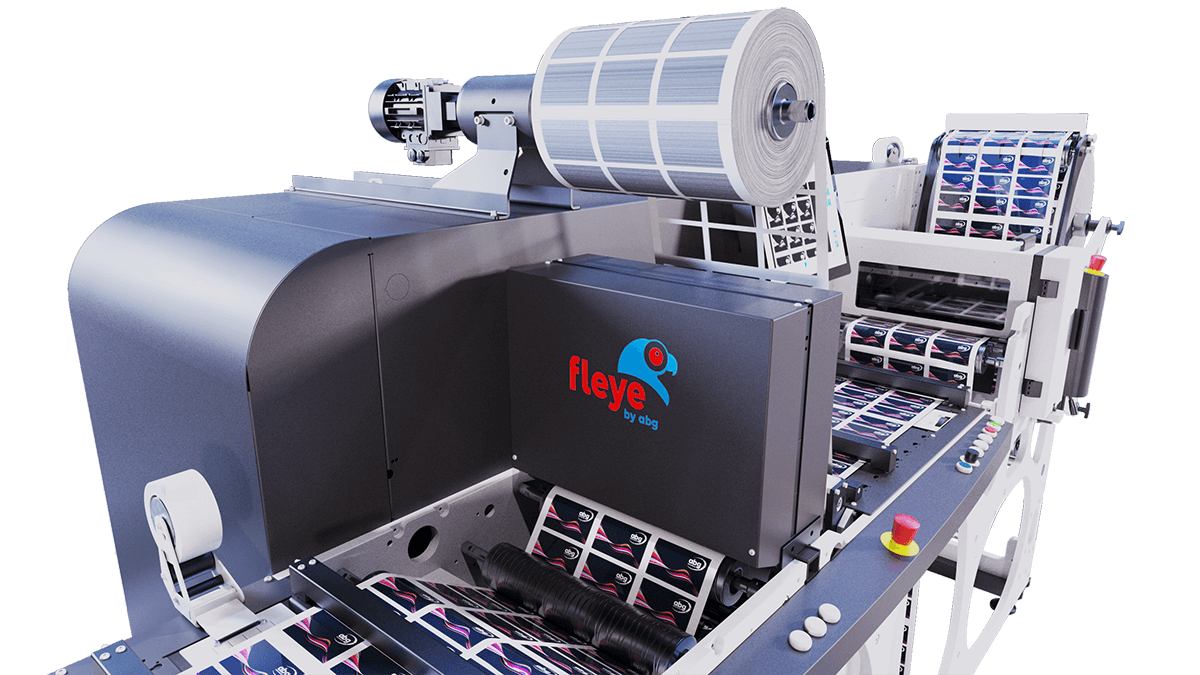

A fresh look at

digital finishing

Innovative digital

finishing machines

Easy to use, quick to set up, fast, automated, flexible

and reliable – just some of the reasons clients across the globe choose ABG machines.